The Technology

Leading Sustainable Concrete Innovations

At the heart of SonoAsh’s mission lies a commitment to revolutionizing the construction sector through sustainable concrete innovations. Our unique ash beneficiation technology sets the stage for a greener, more sustainable future, showcasing our dedication to environmental preservation and efficiency in every project we undertake.

Pioneering Ash Beneficiation Technology

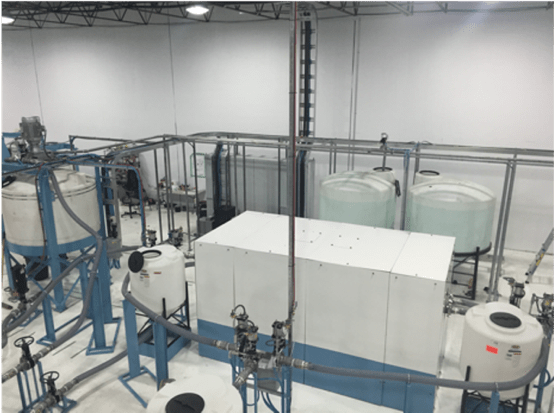

Utilizing our advanced ash beneficiation technology, SonoAsh leads the way in transforming coal combustion residuals into valuable resources for the construction industry. This proprietary technology underpins our efforts to not only create superior building materials but also to advocate for the environment by diverting waste from landfills and reducing the industry’s carbon footprint.

Waste-to-Value Cement Solutions

SonoAsh’s waste-to-value cement solutions epitomize innovation, turning what was once considered waste into highly sought-after construction materials. Through the specialized process of sonication, we unlock the potential of coal ash, converting it into premium components for high-quality, sustainable concrete innovations. This not only contributes to building resilient infrastructure but also elevates the standard for environmental responsibility in the sector.

Coal Ash Processing Solutions

Addressing the pressing need for environmentally conscious disposal and utilization, our coal ash processing solutions offer a seamless, eco-friendly method for managing coal ash accumulation. These solutions are pivotal in transforming stored waste into durable, eco-friendly cement options, reinforcing our commitment to sustainable concrete innovations.

Commitment to Environmental and Economic Rejuvenation

With the urgent attention required for the over 738 coal ash storage facilities in the U.S., SonoAsh’s technology emerges as a beacon of hope for reducing groundwater contamination and promoting rural economic growth. Our ash beneficiation technology goes beyond environmental sustainability; it aims to rejuvenate rural economies by converting stored waste into valuable resources, echoing our vision for a sustainable and prosperous future.

Join the Sustainable Construction Revolution

As we pioneer waste-to-value cement and coal ash processing solutions, SonoAsh invites you to join us in building a sustainable foundation for tomorrow. Together, we are paving the way for groundbreaking sustainable concrete innovations, leading the charge towards a cleaner, more sustainable planet.

Embrace the future of construction with SonoAsh – Where innovation meets sustainability.